Welcome to the world of aluminum extrusion profiles. Today, we’ll delve into their history and the many ways they’re used. These profiles have a long journey from simple uses to being essential in various industries today.

The story of these profiles starts way back in the 19th century. Aluminum extrusion was invented by Sir Henry Bessemer. He found out how to shape aluminum by squeezing it through a die. This marked the beginning of a technology that soon spread across the globe.

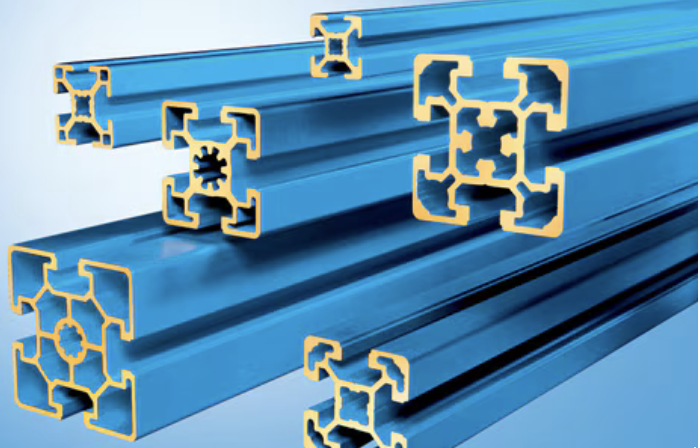

Now, these aluminum profiles are everywhere, from construction to your smartphone. Their great mix of being light, strong, and long-lasting is why they’re so popular. They’re the top choice for anyone wanting both a solid design and a sleek look.

There’s more to love about these profiles. They’re great at moving heat away, which makes them perfect for things that get hot. Plus, they don’t easily wear out, even in tough places. And their ability to be shaped in many ways means we can have these made just right for any job.

Key Takeaways:

- Aluminum extrusion profiles have a rich history dating back to the 19th century.

- They find applications in industries such as construction, automotive, aerospace, and consumer electronics.

- Aluminum extrusion profiles offer a combination of lightweight, strength, durability, and corrosion resistance.

- They have excellent thermal conductivity, making them ideal for heat sink applications.

- Their malleability allows for customization and unique design possibilities.

Understanding Aluminum Extrusion Profiles

Aluminum extrusion profiles are crucial in many industries, like construction and cars. Their making process is important for us to know about.

The process shapes aluminum alloys using controlled steps. It starts with chosen raw materials, like aluminum billets. These are heated and pressed through a mold to get the profile’s shape.

This way of making things lets us design different shapes and sizes. You can make an L shape or something very unique. It lets us meet very specific needs in a project.

These profiles are strong but light. This makes them good for strong yet light things. They also hold up well against rust and other damage from weather.

They’re also very long-lasting. You can make them look good with special finishes. Anodizing or powder coating helps against damage and makes them look nice. This makes them a top pick for buildings and products we buy.

Aluminum profiles also move heat very well. This is great for things that need to stay cool, like in electronics. So, they’re very useful for making parts that keep other things from getting too hot.

“Aluminum extrusion profiles combine strength, durability, and design flexibility, making them an invaluable resource across various industries.” – Ryan Anderson, CEO of ExtrudeX

Aluminum extrusion profiles have changed how things are made. They fit in many different places, from big buildings to tiny parts in cars. They’re known for how well they work and last.

In the next part, we’ll look closer at why these profiles are so useful. We’ll talk more about their special features and what they’re good for.

Advantages of Aluminum Extrusion Profiles

Aluminum extrusion profiles are a top pick in many fields for good reasons. They have several properties that are very helpful. Let’s look at why these profiles are so useful.

Lightweight Nature

Aluminum extrusion profiles are light. This is because aluminum is not very dense. Their strength-to-weight ratio is excellent. Thus, they are perfect for places needing less weight, like in planes and cars.

Durability and Strength

They are also strong and last long. They resist tough weather, extreme heat or cold, and even UV rays. They keep their shape over time, ensuring they work well in tough jobs.

Excellent Thermal Conductivity

These profiles are great at moving heat. Aluminum moves heat well, which is good for keeping things cool when they need to be. It makes them perfect for use in cooling systems and other solutions for managing heat.

They are also great with electricity. This is why they work well for making safe homes for electrical parts and for grounding electricity.

“Aluminum extrusion profiles are an integral part of modern manufacturing processes, offering a wide range of advantages and properties.” — James Thompson, Engineering Consultant

Aluminum extrusion profiles are very versatile. They can be shaped, sized, and finished to fit many different jobs. This flexibility helps them meet the special needs of various areas.

Next, we’ll dive into where these profiles are widely used. Stay with us as we explore the many areas, from making cars and building homes to space travel and electronics. But first, let’s get a sense of how they work:

Key Advantages of Aluminum Extrusion Profiles

| Advantages | Properties |

|---|---|

| Lightweight nature | Low-density metal |

| Durability and strength | Can withstand harsh conditions |

| Excellent thermal conductivity | Efficient heat transfer |

As shown in the table, aluminum extrusion profiles have many perks. This makes them a good, dependable choice for lots of uses. In the next part, we’ll check out where they are key.

Applications of Aluminum Extrusion Profiles

Aluminum extrusion profiles are used in many industries. They are strong, light, and versatile. This makes them a key material in cars, buildings, planes, and tech gadgets.

In cars, they make parts like frames and crash systems. Their strong yet light nature boosts the car’s fuel economy and performance.

For buildings, these profiles mean longer-lasting, low-maintenance structures. They go into windows, doors, walls, and roofs. Apart from the look, they help save energy by keeping buildings warm or cool.

Planes use a lot of these profiles too. They build aircraft bodies, wings, and wheels from them. Their lightness cuts down the plane’s weight. This leads to less fuel use, more stuff on board, and smoother flying.

Consumer electronics also get a lot from these profiles. Think phone cases, laptop shells, LED lights, and coolers. The excellent heat management keeps devices working well for longer.

Aluminum profiles are changing industries by offering new solutions and fueling innovations.

From cars to buildings, air travel to gadgets, these profiles do a lot. They push industries forward with their wide use and benefits.

Customization and Design Flexibility

Aluminum extrusion profiles open up many customization and design options. You can make unique shapes for your projects. This means you can get profiles that fit your needs perfectly.

Because they can be customized, you can get what fits your project. This includes everything from simple shapes to intricate designs. It lets you create products that match your vision exactly.

Aluminum extrusion profiles are highly flexible in design. They can have complex shapes and features. You can create something truly new and innovative.

“Aluminum extrusion profiles provide unparalleled design flexibility, allowing engineers and designers to create products that are not only aesthetically pleasing but also highly functional. The ability to customize profiles with intricate shapes and dimensions opens up a world of possibilities for industries such as architecture, automotive, and consumer electronics.”

You can also choose how to finish these profiles. Options include anodizing, powder coating, or painting. This makes them look good and last longer.

They’re great for making buildings, cars, or gadgets. Their flexibility and customization let you realize your ideas very accurately.

Applications of Aluminum Extrusion Profiles

| Industry | Applications |

|---|---|

| Architecture | Structural frames, windows, curtain walls |

| Automotive | Chassis components, door frames, heat sinks |

| Aerospace | Interior panels, frames, aircraft structures |

| Consumer Electronics | Heat sinks, LED lighting, housings |

| Transportation | Bicycle frames, marine applications, railings |

Aluminum extrusion profiles serve many needs in different fields. They help make a wide range of products. Their adaptability and flexibility are key in many projects.

Conclusion

Aluminum extrusion profiles have a long, rich history. They are crucial in today’s industry. Since they were first used, these profiles have found a place in many different fields. Their lightness, strength, and good heat transfer make them perfect for various projects.

These profiles offer great designs. You can shape them into almost anything a project needs. This makes them really important in areas like cars, buildings, airplanes, and gadgets.

Aluminum extrusion profiles have really changed how we make things. Their history, along with their many uses and benefits, shows their importance. They are key in shaping our modern world, used in buildings, parts, and systems everywhere.

FAQ

What is the history of aluminum extrusion profiles?

Aluminum extrusion profiles have a long history from the early 19th century. The process started in 1797, thanks to British engineer Joseph Bramah. Since then, it has grown a lot, becoming key in many industries.

What are the applications of aluminum extrusion profiles?

These profiles serve many needs across various fields. In cars, they make parts like frames and chassis. They’re also in buildings for windows, curtain walls, and support systems. In areas like aerospace and electronics, their light but strong nature shines.

How are aluminum extrusion profiles manufactured?

The making starts with a die to shape the profile. This die goes into an extrusion press. There, it forces hot aluminum through to take form. After that, the profiles cool, then get cut to size.

What are the advantages of using aluminum extrusion profiles?

These profiles bring loads of benefits. They’re strong but light, helpful where weight is crucial. Their resistance to rust and lasting strength make them great for all sorts of places. Also, their ability to move heat quickly suits many uses.

Can aluminum extrusion profiles be customized?

Yes, these profiles can be tailored a lot. Companies can make them in unique shapes or with cool details for any job. This lets them match many needs and bring fresh ideas to life.

News By Month

Recent Posts

- How Implementing Gravity Conveyors in Your Warehouse Can Improve Productivity

- Visual Management in Action: Real-World Examples to Boost Operational Clarity

- The History and Infinite Applications of Aluminum Extrustion Profiles

- The History and Applications of Unistrut

- Let's Get Moving: Agile Strategies to Accelerate Your Production Line

- Need a Lift? How Advanced Lifting Systems Boost Productivity & Safety

- What are Flow Racks and How Can They Improve Your Manufacturing?

- 2025 Schenker (now DSV)

- Supply Chain Resilience and Risk Management: Building a Stronger Future with Lean Factory America

- Smart Electric Tugs: The Key to Efficiency, Safety, and Well-being in Transportation and Logistics